Is Packaging Really Just About Looks? What Matters Most Actually?

In this era where appearance reigns supreme, many believe packaging only needs to look good. But in reality, packaging serves far more purposes than that. What are the lesser-known yet crucial factors behind commercial packaging that can make your product stand out in a competitive market? Let’s explore them together!

Packaging materials are related to packaging design. Understanding Types of Packaging Box Materials is very important for packaging design and printing.

What are the important factors of packaging?

Let’s first understand them. There are mainly the following points

1️⃣ Functionality Comes First

Attractive packaging certainly catches the eye, but functionality is the foundation. Packaging must not only protect the product but also facilitate transportation, storage, and usage. For instance, food packaging requires airtight moisture resistance, while electronics packaging demands shockproof and drop-proof features. Aesthetically pleasing packaging that proves inconvenient in use is merely superficial.

2️⃣ Integrate Your Brand Story

Successful packaging isn’t just a shell—it must convey your brand’s narrative and values. Let consumers understand your brand through the packaging, fostering connection. For instance, eco-conscious brands use biodegradable materials and print sustainability slogans on packaging, communicating environmental values while elevating brand image. Bonroy Factory fully commits to eco-friendly development, expanding coffee grounds material printing services and adopting biodegradable materials to protect the environment.

3️⃣ Consumer Experience Matters

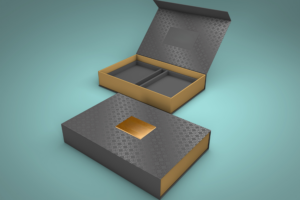

Great packaging design prioritizes user experience. From effortless unboxing to comfortable product access, every detail demands thoughtful design. Packaging that excels in these nuances consistently surprises consumers and builds loyalty. Bonroy holds 9 packaging box patents, featuring innovative designs and eco-friendly materials—join us on the path to innovation!

4️⃣ Differentiated Competition

In a highly homogenized market, how do you make your product stand out on the shelf? Unique packaging design is key. Through innovative shapes, distinctive materials, and exquisite printing techniques, make your packaging stand out and capture consumers’ attention.

5️⃣ Environmental Sustainability

As eco-consciousness grows, consumers increasingly prioritize packaging sustainability. Using recyclable or biodegradable materials not only wins consumer favor but also aligns with environmental trends, enhancing your brand’s social responsibility.

Packaging design is a comprehensive art form that must balance aesthetics with functionality, brand storytelling, user experience, competitive differentiation, and environmental responsibility. Only by holistically considering these elements can truly exceptional commercial packaging be created.

Next, let’s take a look at the main types of Packaging Box Materials.

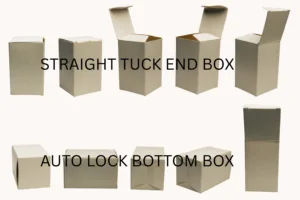

Packaging raw materials are primarily categorized as follows:

- Coated Paper

Features a smooth, glossy surface with high resistance to bending.

Available in C1S glossy art paper (smooth on one side for gloss printing) and C2S glossy art paper (smooth on both sides for double-sided printing) varieties.

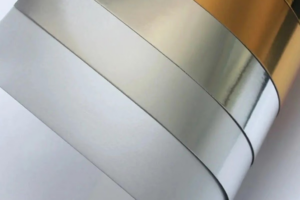

- gold/silver paper

Utilizes UV transfer printing for enhanced gloss and texture compared to standard paper. Includes glossy/matte metallic cardstock, holographic silver, and other specialty cardstocks.

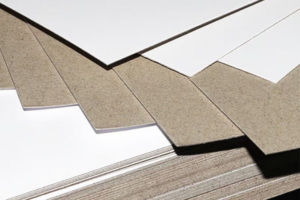

- Cardboard

Manufactured from pulp, featuring substantial thickness and rigidity. Primarily includes white cardboard and gray cardboard.

- SpecialPaper

Includes kraft paper (high strength, low cost, breathable, tear-resistant), embossed paper, black cardstock (premium texture, thick, high tensile strength), tracing paper (high strength, low water absorption, corrosion-resistant), and white cardstock (sturdy, thick, smooth, cost-effective)

- Corrugated Paper

Lightweight yet sturdy, with strong load-bearing and pressure resistance.

Corrugated cardboard is formed by bonding face paper, liner paper, fluting paper, and corrugated paper processed into a wave pattern. Corrugation height: A > C > B > E

| Flute Type | Flute Height (mm) | /30cm | Flat Crush Strength | Vertical Crush Strength | Parallel Crush Strength | Cushioning | Characteristics |

|---|---|---|---|---|---|---|---|

| A Flute | 4.5–5.0 | 32–36 | Fair | Excellent | Fair | Excellent | Highest compression strength but easily damaged. Good elasticity and cushioning. Commonly used for outer cartons and partitions. |

| B Flute | 2.5–3.0 | 46–50 | Excellent | Fair | Excellent | Fair | Lower strength but good stability. Smooth surface with high flat crush resistance, suitable for printing. Used for cartons, boxes, partitions, and liners. |

| C Flute | 3.5–4.0 | 36–40 | Good | Good | Good | Good | Strength between A and B flutes. More economical. Most common type in mainland China. |

| E Flute | 1.1–1.4 | 92–100 | – | – | – | – | Thin and dense. Lightweight with good cushioning. Cost-effective with excellent printing results. Suitable only for fine inner packaging, not for outer cartons or protective cushioning. |

Inner Lining Materials:

To facilitate fragile item packaging or enhance gift box aesthetics, various inner linings are used, primarily including:

Paper inserts are lightweight, eco-friendly, and ideal for books, stationery, and simple protective needs.

Sponge inserts provide soft cushioning and are often used for fragile items such as cosmetics, glassware, or electronic accessories.

EVA inserts offer high durability, precision cutting, and strong protection, making them suitable for luxury products, electronics, and high-end gift boxes.

Pearl cotton (EPE) is lightweight, flexible, and shock-resistant, commonly used for appliances, instruments, and larger fragile goods.

Blister packaging provides a clear display and secure positioning, making it perfect for retail products, cosmetics, toys, and small electronics.

When it comes to selecting the most suitable packaging material, there is no one-size-fits-all answer. Every business must evaluate its priorities and strike a balance between budget, functionality, and brand image. To simplify the decision-making process, let’s break it down into three key factors:

Costs:

Your budget often defines the range of materials you can consider.If affordability is your top concern, cardboard or kraft boxes provide cost-efficient solutions for everyday packaging.For premium products, the higher cost of rigid boxes may be justified by the value they add to your brand perception.

Durability:

Packaging must ensure that products reach customers safely.Corrugated boxes are the most reliable for shipping heavy or fragile items, thanks to their shock-absorbing fluted layers.For less demanding uses, cardboard and kraft offer sufficient strength at a lower cost.

Customization Options:

Packaging is also a branding tool—your box is often the first physical touchpoint between you and your customer.Materials like cardboard and rigid boxes offer the widest range of customization, from vibrant printing to luxury finishes like embossing, foil stamping, and matte lamination.Eco-friendly kraft or recycled materials may support fewer finishes, but they communicate sustainability, which can strongly resonate with today’s consumers.By weighing these three aspects—costs, durability, and customization—you can identify the material that not only protects your products but also communicates your brand’s story effectively.

Learn about Types of Packaging Box Materials, make your own boxes, bonroy factory provides any custom packaging boxes you want.