Introduction

The global demand for cardboard boxes has skyrocketed in recent years, driven by e-commerce growth, logistics needs, and a strong focus on sustainable packaging. For businesses and entrepreneurs, understanding the profitability of cardboard box manufacturing is essential before entering this market.

This guide provides a complete overview of the materials, types, manufacturing processes, and profit potential of cardboard boxes, while also highlighting the benefits of partnering with a professional printing and packaging manufacturer like us.

What are Cardboard Boxes Made of?

Cardboard boxes are primarily made from paper-based materials such as:

Kraft paper – known for its durability and eco-friendliness.

Corrugated cardboard – a layered structure that provides strength for shipping.

Recycled paper – sustainable and cost-effective for environmentally conscious brands.

For more information on packaging raw materials, please refer to this article:

Types of Packaging Box Materials: Costs, Durability & Customization Options

As demand for sustainable packaging continues to grow, innovative materials such as compostable substances, sugarcane bagasse, bamboo, and seaweed-based plastics are emerging as promising alternatives to traditional packaging materials. These eco-friendly materials offer numerous benefits, from reducing carbon footprints to providing biodegradable options made from renewable resources. At Bonroy, we are excited to explore these new materials and bring them to market, delivering customized sustainable packaging solutions tailored to meet the needs of diverse industries.

The choice of material directly affects the box’s strength, print quality, and cost. For B2B clients, investing in high-quality printed boxes can enhance brand recognition while ensuring safe product delivery.

Tip for Businesses: Combining strong materials with high-quality printing can increase perceived value and customer satisfaction.

Types of Corrugated Boxes

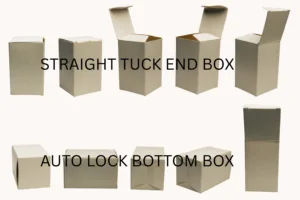

Cardboard boxes come in various forms to meet different product and shipping requirements:

Single-wall boxes – lightweight and suitable for most standard shipments.

Double-wall boxes – stronger, ideal for heavier items or long-distance shipping.

Triple-wall boxes – maximum durability for industrial shipments.

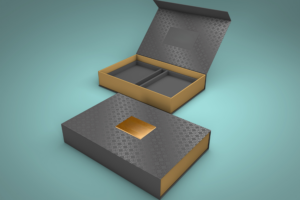

Custom printed boxes – for e-commerce, luxury products, and promotional packaging.

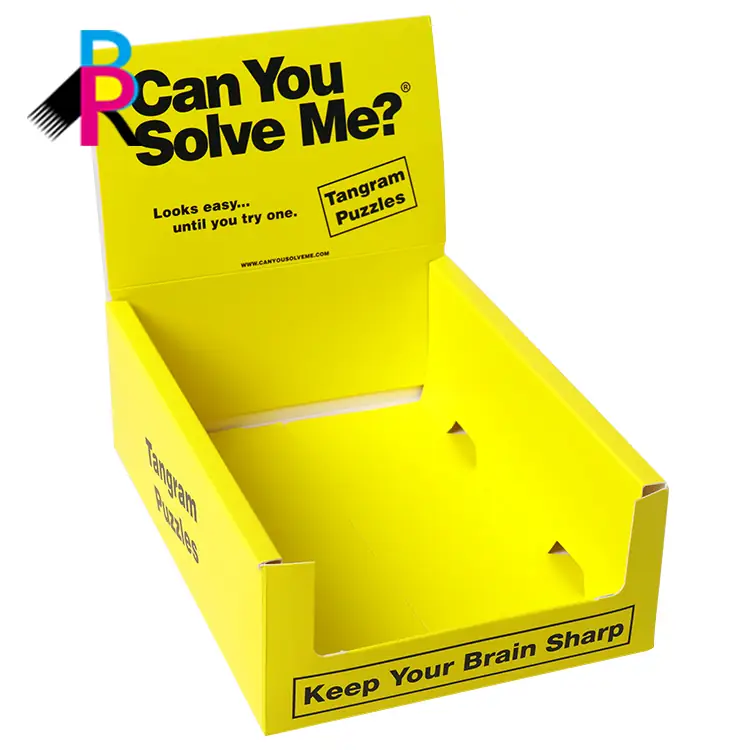

Display boxes – designed for retail showcasing and marketing purposes.

Understanding the right type for your product is key to optimizing costs and ensuring product safety.

Cardboard Business Ideas

For businesses exploring the cardboard packaging industry, several opportunities exist:

E-commerce packaging – tailor-made boxes for online retailers.

Branding through custom boxes – premium printing enhances customer experience.

Eco-friendly packaging – sustainable materials attract environmentally conscious consumers.

Small batch production – flexible services for startups or niche products.

By understanding market trends, businesses can identify profitable niches and differentiate themselves from competitors.

How Profitable Is the Cardboard Box Business?

Profitability in cardboard box manufacturing depends on several factors:

Material costs – fluctuating paper and printing material prices affect margins.

Production efficiency – modern machinery reduces labor costs and waste.

Customization and branding – premium printed boxes allow higher pricing.

Market demand – e-commerce, food, and logistics sectors continue to expand globally.

With proper planning, efficient production, and high-quality output, the cardboard box business can offer strong ROI. Many suppliers report profit margins ranging from 15% to 40%, depending on scale and product type.

Why Partner with a Professional Box Manufacturer?

Choosing an experienced packaging supplier brings numerous benefits:

Consistent quality – reliable materials and skilled production teams.

Cost efficiency – optimized processes reduce waste and unnecessary expenses.

Design expertise – professional printing and structural design elevate your brand.

Global experience – familiarity with international shipping and regulations ensures smooth B2B operations.

As a trusted packaging manufacturer, we provide full-service solutions including custom printing, high-volume production, and sustainable material options. Working with us helps businesses focus on growth while leaving packaging logistics to the experts.

Conclusion

Cardboard box manufacturing remains a profitable and growing business, particularly for companies offering high-quality, customized, and sustainable packaging solutions. Understanding materials, production processes, and market trends is essential to maximize profits and attract high-value clients.

Whether you are exploring new business ventures or seeking a reliable B2B packaging supplier, partnering with a professional manufacturer ensures superior quality, cost efficiency, and timely delivery.

Contact us today to explore custom cardboard box solutions tailored for your business needs.