Rigid packaging stands as one of the most premium and durable packaging solutions in modern product manufacturing. With its sturdiness, structural integrity, and luxurious appearance, rigid packaging has become the preferred choice for high-end brands seeking to create memorable unboxing experiences and deliver exceptional product protection.

But how does rigid packaging differ from the other two major packaging categories—folding cartons and corrugated boxes? When should businesses opt for one over the other?

This guide provides a comprehensive breakdown:

• Definition of rigid packaging

• Material composition

• Manufacturing processes

• Application scenarios

• Key advantages

• Limitations

• Detailed comparison with folding cartons and corrugated boxes

Whether you are a brand owner, product developer, procurement specialist, or packaging designer, this guide will help you understand rigid packaging’s position in today’s market and master the essentials for selecting the optimal packaging solution for your products.

What Is Rigid Packaging?

Rigid packaging refers to containers made from thick, sturdy cardboard that resists folding, bending, or collapsing. Typically 4-5 times thicker than standard folding carton material, it offers exceptional durability and a premium tactile feel. It does not bend or collapse under pressure. It maintains its shape from production through delivery, remaining stable during transport, storage, and on retail shelves.

Its structure is typically formed through:

– Solid corrugated cardboard or grayboard core

– Wrapped in printed specialty paper

– Surface coated with varnish, laminate, foil, or composite materials

Unlike foldable cartons that flatten for shipping, rigid packaging cannot be transported flat and possesses a permanent shape.

Core Characteristics of Rigid Packaging

· High structural strength

· Luxurious visual and tactile appeal

· Suitable for luxury goods or fragile items

· Supports diverse customization

· Resistant to collapse and folding

Rigid packaging boxes are widely used in jewelry, cosmetics, electronics, gift packaging, premium beverages, and promotional items.

2. Common Types of Rigid Packaging

Rigid packaging can take many structural forms. Below are the most commonly used types:

2.1 Rigid Setup Box (Two-Piece Box)

Often used for luxury items:

Top lid + bottom base

Strong structure

Ideal for electronics, premium cosmetics, and gift sets

2.2 Magnetic Closure Rigid Boxes

Features an elegant magnetic flap that snaps into place:

Popular for tech accessories, influencer kits, and premium brands

Excellent for unboxing experiences

2.3 Drawer / Slide Rigid Boxes

Sleeve + inner tray design:

Creates a high-end reveal

Often used in jewelry, fragrance, and stationery

2.4 Round / Cylindrical Rigid Boxes

Made from rolled rigid board:

Used for candles, foods, teas, fashion accessories

Rigid packaging is highly customizable in shape, opening style, inserts, and overall design.

3. Materials Used in Rigid Packaging

Rigid packaging uses stronger materials compared to folding cartons.

3.1 Greyboard / Chipboard

The core material for most rigid boxes

Thickness ranges from 1mm to 3mm

Provides structural strength

3.2 Wrapped Paper

The outer covering that provides aesthetics:

Art paper

Kraft paper

Textured specialty paper

Fabric or leatherette paper

Foil paper

3.3 Inserts

To secure products inside:

EVA foam

Paperboard insert

Foam board

Molded pulp

Because the board is thick and wrapped, rigid packaging offers both protection and aesthetic versatility.

4. Advantages of Rigid Packaging

Rigid packaging provides brand and product benefits not achievable with other packaging types.

4.1 Premium Branding and Shelf Appeal

The strong structure and wrapped finishes create a luxury feel that elevates product value.

4.2 High Structural Strength

Protects delicate, fragile, and expensive items.

4.3 Exceptional Customization Options

Supports:

Embossing & debossing

Foil stamping

Spot UV

Laminations (matte, gloss, soft-touch)

Window cutouts

Magnetic closures

Specialty textures

4.4 Excellent for Unboxing Experiences

Influencer and social media marketing favor rigid boxes for their premium reveal.

4.5 Long-Term Reusability

Many consumers repurpose rigid boxes for storage, extending brand visibility.

5. Limitations of Rigid Packaging

Despite its many strengths, rigid packaging has restrictions.

5.1 Higher Cost

Rigid boxes cost more due to:

Thick board

Hand-assembly

Additional wrapping and finishing processes

5.2 Higher Shipping Costs

Because rigid boxes cannot “collapse flat,” they occupy more space during transport.

5.3 Longer Production Time

Many rigid boxes require manual labor, extending lead time.

5.4 Less Eco-friendly When Over-laminated

Some finishing methods reduce recyclability unless eco-friendly options are chosen.

6. What Are Folding Cartons?

Now let’s compare rigid packaging with folding cartons.

Folding cartons are packaging made from thinner paperboard (usually 250–400gsm) that can be folded flat.

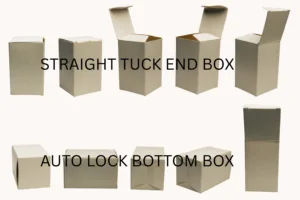

Examples include:

Tuck-end boxes

Snap-lock bottom boxes

Hang tab boxes

Display cartons

Benefits of Folding Cartons

Lower cost

Lightweight

Ships flat, saving logistics cost

Easy to print and customize

Limitations

Less durable

Not suitable for luxury positioning

Cannot carry heavy products without reinforcement

7. What Are Corrugated Boxes?

Corrugated boxes are made from fluted corrugated board, consisting of:

An outer liner

A fluted layer

An inner liner

They offer excellent strength for shipping and heavy goods.

Benefits of Corrugated Boxes

Maximum strength and protection

Ideal for e-commerce and logistics

Cost-effective

Fully recyclable

Limitations

Not as visually premium as rigid packaging

Bulkier than folding cartons

8. Rigid Packaging vs. Folding Cartons vs. Corrugated Boxes

Below is a detailed comparison to help businesses choose the right packaging solution.

8.1 Structural Strength

| Packaging Type | Strength Level | Notes |

|---|---|---|

| Rigid Packaging | ★★★★☆ | Strong and durable, does not collapse |

| Folding Cartons | ★★☆☆☆ | Lightweight, less resistant to impact |

| Corrugated Boxes | ★★★★★ | Best option for protection and shipping |

Rigid is strong, corrugated is the strongest.

8.2 Visual Appeal

| Packaging Type | Visual Quality | Notes |

|---|---|---|

| Rigid Packaging | ★★★★★ | Most luxurious and premium |

| Folding Cartons | ★★★☆☆ | Clean, printable, but less premium |

| Corrugated Boxes | ★★☆☆☆ | Usually plain unless printed |

Rigid boxes are ideal for luxury branding.

8.3 Customization Options

| Packaging Type | Customization | Complexity |

|---|---|---|

| Rigid | Highest | Options include magnetic closures, wrapped textures, complex shapes |

| Folding Carton | Medium | Simple box structures, printing, coatings |

| Corrugated | Low–Medium | Mostly structural customization, limited luxury finishes |

Rigid boxes allow the most sophisticated upgrades.

8.4 Cost Comparison

| Packaging Type | Cost Level |

|---|---|

| Rigid Packaging | High |

| Folding Cartons | Low |

| Corrugated Boxes | Medium |

Rigid packaging is the most expensive due to materials and labor.

8.5 Shipping & Storage Efficiency

| Packaging Type | Efficiency |

|---|---|

| Rigid Packaging | Low (non-collapsible) |

| Folding Cartons | Excellent (ships flat) |

| Corrugated Boxes | Good |

Folding cartons offer the greatest logistics savings.

8.6 Best Use Cases

Rigid Packaging

Luxury products

Cosmetics & skincare

Jewelry

Electronics

Premium gifts

Brand experience boxes

Folding Cartons

Lightweight retail products

Food, beauty, supplements

Point-of-sale displays

Inner packaging

Corrugated Boxes

Shipping

E-commerce

Heavy goods

Protective secondary packaging

9. Packaging Trends in 2025: Where Rigid Packaging Stands

Rigid packaging continues to evolve. Key trends include:

9.1 Sustainable Rigid Packaging

Recycled greyboard

FSC-certified wrap papers

Plastic-free inserts

Water-based inks

9.2 Premium Unboxing for E-commerce

Brands invest heavily in:

Magnetic boxes

Drawer boxes

Personalized inserts

9.3 Hybrid Packaging

Rigid outer shell + corrugated inner support for fragile products.

9.4 Minimalist & Soft-Touch Design

Matte soft-touch laminations and simple typography dominate luxury branding.

9.5 Automation in Rigid Box Production

More suppliers adopt semi-automatic equipment to reduce cost and lead times.

Rigid packaging remains the standard for premium positioning.

10. How to Choose the Right Packaging for Your Product

To make the right decision, consider:

10.1 Product Weight & Fragility

Heavy or fragile → corrugated or rigid

Lightweight → folding carton

10.2 Brand Positioning

Luxury & gifting → rigid

Mainstream retail → folding carton

10.3 Budget

Tight budget → folding carton or corrugated

High-value item → rigid

10.4 Logistics Requirements

Need flat shipping → folding carton

Accept full-size shipping → rigid

10.5 Consumer Experience

Want a “wow” unboxing → rigid packaging

11. Conclusion

Rigid packaging plays a crucial role in shaping premium brand identity and protecting high-value products. Its durability, sophisticated finishes, and luxurious feel set it apart from folding cartons and corrugated boxes.

If you need luxury, structure, and a memorable unboxing, choose rigid packaging.

If you need cost efficiency and versatility, choose folding cartons.

If you need maximum strength for transport, choose corrugated boxes.

Understanding the strengths and limitations of each packaging type allows brands to make strategic decisions that balance cost, performance, and aesthetics. In today’s competitive marketplace, choosing the right packaging is not just a logistics decision—it is a branding strategy that shapes customer perception and long-term loyalty.

Partner with Bonroy and build your rigid packaging business!